top of page

Aluminum Brazing

Solution

● What is brazing?

• Brazing is the melting point of the base metal to be joined at 450°C or higher. POINT) In the following, the base material is not damaged and it is a technology to join two base materials by applying heat and filler metal.

• More specifically, with LIQUIDUS TEMPERATURE above 450°C.

Using filler metal and applying heat below the solidus temperature of the base material (SOLIDUS TEMPERATURE)

The method of joining two base materials can be called brazing.

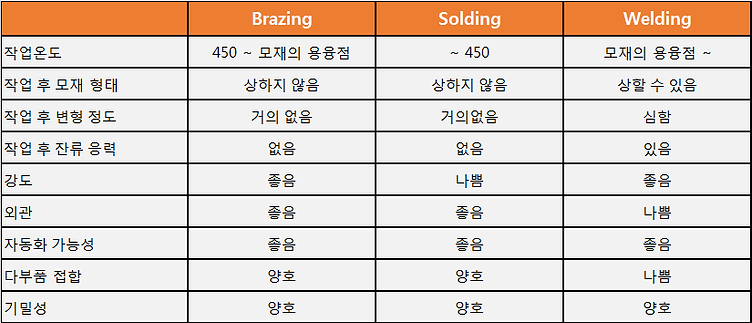

• For reference, the methods of joining with filler metal are mainly welding and braying.

It can be divided into brazing and soldering. Welding is often done by welding,

Brazing is sometimes referred to as brazing, and soldering is sometimes referred to as soft soldering.

• The difference between the above three methods is that soldering uses a filler metal below 450°C.

Welding and brazing are performed at a temperature of 450°C or higher, but the difference is that welding is

It is a method of joining above the melting point of the base material to be joined.

Brazing does not damage the base metal below the melting point.

It refers to the technology of joining two base materials by applying heat using filler metal.

● Principle of brazing

• Constant temperature during brazing (BRAZING TEMPERATURE), brazing material (BRAZING)

FILLER METAL) melts and seeps between the two molten materials to be brazed.

It can be called brazing.

• At this time, the property indicating the degree of affinity between the sheep base material and the filler metal is called wettability.

It can be expressed as (WETTING) and flows through the joint gap of both base materials.

This phenomenon can be expressed as capillary action.

• In this case, of course, GRAVITY can act. However, the main basic principle of brazing is

After heating the base material, add filler metal and join, the amount of filler material is increased by wetting.

It melts in the base material and flows between both base materials by capillary action.

it can be said that

• If the filler metal has poor wettability with the base material to be brazed, it may not be able to join.

However, if the joint interval is large, the filler metal is not filled between both base materials, so it is incomplete.

It will be a full junction.

• In general, when the base material is left in the air for a long time during brazing, or when it is heated,

When it is in an inactive state due to the formation of oxides, etc. by combining with oxygen, etc., the liquid metal is

Wetting will be difficult.

• Also, when brazing metal, use flux or in a reducing atmosphere or vacuum atmosphere.

Heating will suppress the formation of oxides so that the filler metal is well wetted. this thing

When finished, the filler metal should flow well between both base metals by correct capillary action.

• In particular, the capillary phenomenon affects the precision of the workpiece to be brazed and There are many connections. bree

If the product cannot be designed ideally for easing, workability will decrease and cost will increase.

This will lead to an increase in the defect rate.

• That is, when brazing, gravity acts naturally, and when assembling products, gravity

will have to be taken into account.

Capillary action and gravity greatly affect the flow of the molten metal, and wetting is the

It has a lot to do with affinity.

● Wetting

• When filler metal is melted, is there affinity with the base material according to the degree of wettability?

Whether there is no or not, FLUX or ATMOSPHERE plays a role.

will be the yardstick.

When a drop of liquid (DROPLET) is dropped on a flat flat surface of a solid state to explain this wettability

Consider the case.

• Of course, gravity is neglected in this case, and chemical reactions in solid, liquid, and gas phases are also ignored.

• Here, the surface tension of the solid phase (base metal) is γSL, the surface tension of the liquid phase (filler material) is γSU, and the surface tension of the solid phase (base metal) is γSU.

If the surface tension of the interface is expressed as γLV, it can be expressed in the following way.

θ is the contact angle. : COSθ = (γSV-γSL)/γLV

• The boundary between whether wetting occurs or not can be thought of as 90° (θ angle). i.e. angle

If it is less than 90°, there is wettability, and if it is more than 90°, wettability will not occur.

In general, for most brazing, the θ angle is between 10° and 40°. This is mostly brazing

It is determined by the joint spacing of the base material.

● CAPILLARY ACTION

• Capillary action is a very important physical phenomenon in the brazing process. Solvent flow is

Force due to capillary action, viscosity, density of molten metal, and position of the bonding surface against gravity

depends on

In general, the viscosity that inhibits the flow of slag is correlated with the temperature in the molten state.

• It can be seen that as the temperature increases, the viscosity affects the viscosity.

• In other words, it can be seen that the fluidity of the slag increases as the temperature increases.

In any case, capillary action is a very important physical

force, and as described above, it has a very close relationship with the JOINT GAP.

In addition, the type of molten material, viscosity, density, position of the bonding surface for increasing force, heating method, etc. are very important.

have a close correlation.

bottom of page