top of page

Nickel Brazing

Solutions

● Comparison of other companies

1. Comparison of BNi-2 paste (Dawon / company K )

One) Analysis agency: KTR Korea Testing and Research Institute for Chemical Convergence

2) Test specification

3) test equipment

- Scanning Electron Microscopy (JEOL JSM-6490LV)

: EDS (OXFORD INSTRUMENT - INCA, X-STREAM)

4) Test method

a. Prepare the specimen as shown in the figure on the right to meet the AWS B2.2 standard

b. The paste is applied to the area marked in red in the center of the drawing and then brazed.

c. Picture after brazing (below)

d. Check the tensile strength, wettability, and stable density of the specimen

5) Test Result – 1: Tensile TEST

: The tensile strength Same level and base metal fracture. (meaning higher weld strength)

6) Test result – 2: wettability TEST

: AWS B2.2 standard is 20% or less to pass. Both products have very good wettability and are at the same level.

7) Test Results – 3: SEM Picture

a. Dawon Chemtech : The density is constant and there is no crack.

b. K's product: Many cracks occur on the surface. → Depending on the conditions, the level of pyrolysis of the binder is suspected

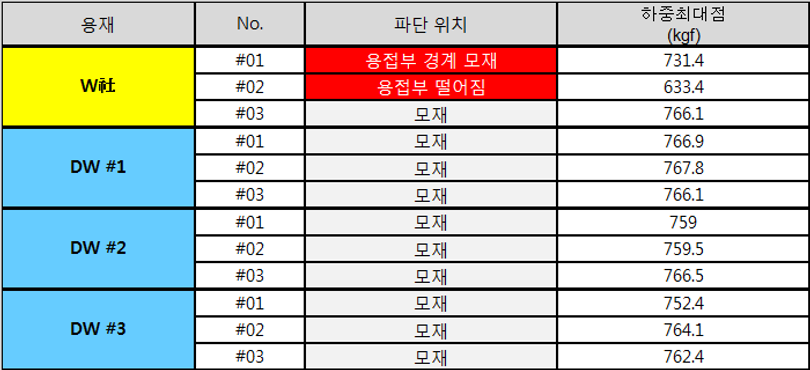

2. Ni-685 Paste comparison (Dawon / Company W )

1) Data comparison company: W company product user

2) Test result – 1: Tensile TEST

: Test the tensile strength by applying the same amount of paste to the joint of the same specimen and brazing.

a. Compared to company W, the tensile strength of the joint is high and the defect rate is low.

b. Judging from the wettability test results of Test Result-2, the higher the wettability (permeability), the wider the bonding area.

It was judged that the tensile strength was high.

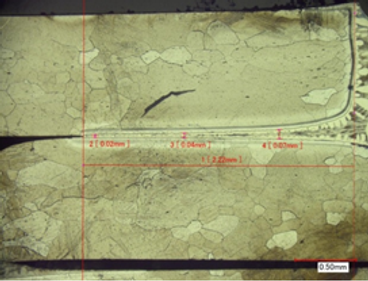

3) Test result – 2: wettability TEST

: Apply the same amount of paste to the joint of the same specimen and check the permeability of the pressure material by brazing.

a. The permeability of the joint is higher than that of Company W.

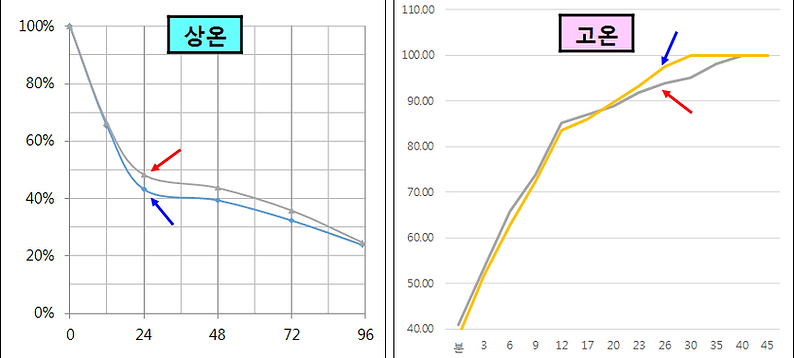

4) Workability improvement completed

a. Optimization of room temperature and high temperature drying properties

- High-temperature drying to improve productivity

- Optimization of dryness at room temperature to a level that does not affect workability

: Printing type automation equipment is not suitable for continuous operation if drying is too fast.

Problems arise and lot deviations occur.

b. Reduced vacuum replacement time

- By improving the high temperature drying time, the vacuum replacement time is shortened by more than 30%.

※ Dawon Chemtech always compares products with global products and

We are improving.

A product that is better than the product you are currently using

We will continue to strive to provide it.

bottom of page